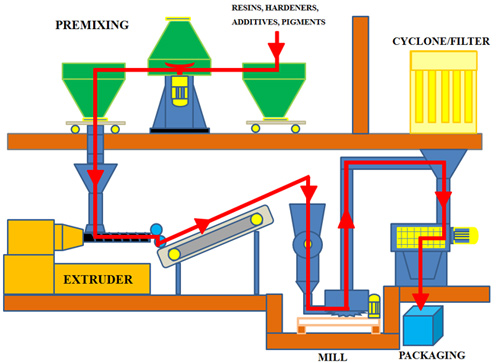

The process starts from melt mixing of raw materials using extruder or compounder. This mixed material is then flattened, cooled and fine grounded to the appropriate particle size for application. Hence, there are three principal stages: Premixing, Extrusion and Grinding.

(a) Premixing

A homogeneous mixture of the raw materials is prepared prior to extrusion. Careful weighing of all raw materials are combined and mixed as homogenous as possible to yield powder of the required color and specification.

(b) Extrusion

The approved premixing ingredients are passed through an extruder to ensure maximum dispersion, short residence time and controlled melting temperature. The extrudate, discharged from the extruder, is rapidly cooled through rollers to become a thin sheet and its temperature is reduced further. The sheet is then kibbled into small chips ready for the next stage.

(c) Grinding

The granulated chips are then fed through a grinding mill, consist of a rotor, classifier and cyclone, to become Powder Coatings with proper particle size distribution. Control of PSD is essential for successful application.